2-up off-line for smaller star-folded bags

The design of our new Starline has been based on our proven technology and long experience for machines running off-line. Starline ensures reliable, robust and simple production and gives you the lowest possible production cost per bag.

Technical data

- Master roll diameter max, mm [in]

Master roll width max, mm [in]

Web width sealing max, mm [in]

Bag length, min-max, mm [in]

Machine speed, m/min [fpm]

Cycles/ min, max

Roll changes/ min, max

Winding width, max, mm [in]

Roll diameter, max mm [in]

Installed power, kW [Amps]

Air supply, bar [psi]

L x W x H, mm

L x W x H, [in]

Weight, kg [lbs]

Working temp °C [°F]

- 2 x 800 [2 x 31.5]

2 x 460 [2 x 18]

2 x 460 [2 x 18]

550-3000 [16-118]

20-100* [65-330*]

320 / 2 Lanes

2 x 8

2 x 230 [2 x 9]

150 [5.9]

5 [9]

6 / 13 lt /roll change [87]

5900 x 2400 x 2200

232 x 95 x 87

2900 [6380]

5 to +40 [+40 to +105]

* Mechanical Max production speed depending on the quality (i.e. thickness, number of layers etc) of material to be converted.

Mainpower All units mainpower 380–420V +10%/-15%, for temporary power surge, 16A, 3phases, 50Hz, ground and neutral.

All technical data are subject to change without prior notice.

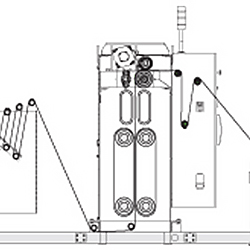

Off line configuration

All changes/adjustments of running parameters from one location (one operator panel). Servo driven. Tensionless sealing system from two sides. Can convert PE of HD, MD, LD, LLD, Bio and recycled material

Options

Driven exit nip on folder. Automatic tape unit on winder. Expansion shaft, unwinder. Photocell. Dancer, bagmachine. Knife heater. Stop indicator, unwinder.

© Copyright 2024 FAS Converting Machinery AB. All rights reserved.

Contact webmaster

Privacy Policy and Terms Of Service | Cookie Policy

FAS Converting Machinery AB.

Virvelvägen 5, SE-232 36 Arlöv, Sweden.

Phone: +46 (0) 104 050 500. Mail to Headoffice

FAS Converting Machinery Inc.

20 Industrial Road, Fairfield NJ 07004, USA.

Phone: +1 973 882 0512. E-mail