Make your way … to the K. Trends by Eli Schloss. Less paper in the end products and much more …

This newsletter’s guest editor is Eli Schloss of Corepac LLC

Trends in Packaging Automation

From time to time FAS and Peco invite industry experts to write about topics that we think would be of interest to you our readers. This month Eli Schloss, experienced system integrator for automated packaging solutions for many Film Converting applications, shares some thoughts about packaging automation.

The increased competition for Shelf Space, with the drive to create a unique product for each customer, has generated a condition that requires frequent equipment change-overs for manufacturers. While changing from product to product at the extruder/winder level is unavoidable, calibrating any automatic packaging system down the line is cumbersome and can typically take up to 30 minutes.

Historically the solution has been to add labor which performed the packaging operation at the end of each production line. Some recent changes to the job market are a contributing factor to introduce the benefits of automation:

• Retaining qualified employees

• Rise in minimum wage

• Repetitive hand motion (carpel tunnel)

• Increase in small batch requests, inserting more downtime to the process.

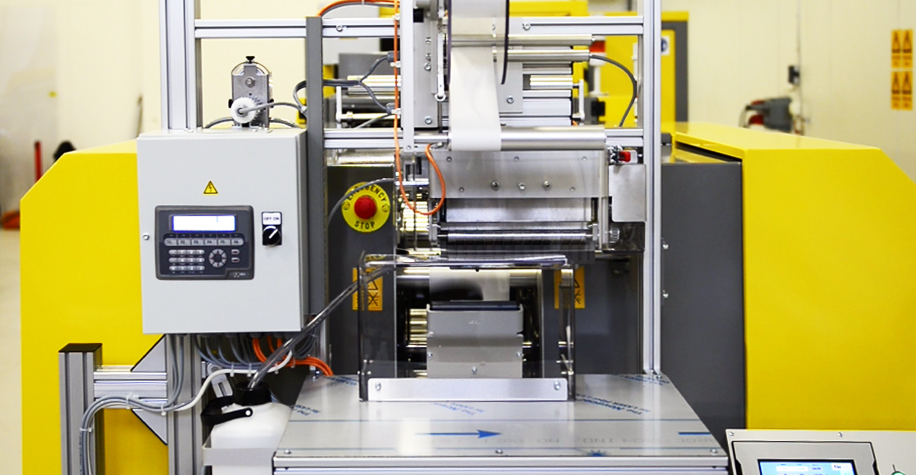

By introducing the fully “servo” adjustable packaging line, the integrated line is designed to accept the product roll from the winder and process it through the packaging, labeling, palletizing, and stretch wrapping stations.

By utilizing a combination of robotics and servo driven equipment, this line can be adjusted to another product in minutes, dramatically decreasing change-over downtime.

Automation provides manufactures the ability to offer customized solutions to clients while reducing cost and lost production time.

Updating to an automated package line offers multiple payback scenarios which include:

• A single operator can supervise up to 7 lines (dependent on the physical distance between lines)

• Increase in consistency of the final product

• Increased efficiency

• Ability to run the process at top speed

• Ability to track in line/employee performance

Eli Schloss, Corepac LLC

Tel: 732-668-7223. Email directly here

Eli Schloss is actively involved in the automating converting industry for the past ten years. With a background in system design, manufacturing, and installation; Corepac can assess and implement cost-saving automation for a wide verity of packaging needs.

If you have questions for the author, you can contact Eli directly.

If you have comments for FAS about our guest authors program, including suggestions for future topics you’d like covered, please contact us at Peter.hakansson@fasconverting.com

Help reduce paper consumption – Save Trees!

When North American consumers purchase trash bags they nearly always come in a box. The box sometimes acts as a dispenser for the bags while they last, but in all cases is an advertisement vehicle for the producers, and retailers of the bags.

In Europe however, in an effort to reduce packaging’s impact on the solid waste stream consumers have grown accustomed to, and in fact prefer purchasing their bags not in a box, but simply wrapped with a printed label. At FAS we call this label Banderoll™

85% less paper is used to label a roll as compared to putting that roll in a box.

Here is a photograph comparing a trash bag section in a major grocer in the USA on the right and in central Europe on the left. All Peco FAS winders, new and old can be outfitted with the ability to apply such a label for a roll that will look like the image in the middle.

You can assist your customers to develop a cost effective environmentally friendly alternative for packaging their trash bag rolls.

The push to reduce packaging is one we are all familiar with, and we at Peco FAS believe this will be in our future. Again tons of paper is saved, and not introduced into our solid waste stream.

Image on the left: Paper tape and a box. Image on the right: Our environmentally friendly alternative Banderoll™.

Example, a roll with paper tape Banderoll™ vs box:

Weight of Banderoll™: 3 gram

Weight of box: 21 gram

Difference: 85% less paper used!

Apart from the obvious paper savings, the other advantages to this method of roll presentation are:

Lower capital costs in your factory (much less equipment required to wrap a roll as compared to fabricating, erecting a box, inserting a roll into the box and gluing the box closed.

Less material handling pallets of folded card board boxes are replaced with rolls of paper

Easier product handling at the retail outlet.

More product will fit on the retail shelf. Rolls of bags that are banded, not boxed, take up less shelf space so more can be stocked at any given time, saving the retailer time and cost by less frequent restocking’s required.

Find out from your Peco FAS sales professional how you can outfit your coreless winders to present your rolls of bags finished with our Banderoll™ system, saving money for all, while protecting our environment.

Message from Stefan Berg, CEO of FAS Peco

Since joining FAS, one of the most important aspects of my role has been getting to know our customers and understanding their needs.

I have met many of you at exhibitions, in your plants, and during your visits to our Innovation Center here in Sweden. I look forward to meeting more of you in the month leading up to the K-2019 fair in Düsseldorf.

As a company, our challenge is straightforward:

We want to be a more valued supplier, your first choice for Film Converting solutions.

We have heard your ideas, comments and suggestions as to how we might achieve that.

Recently we hired a market research firm here in Sweden to contact a number of you and conduct an independent interview seeking your thoughts and comments about FAS Peco as a partner and supplier to your business.

The results are interesting.

You have told us many positive things about our company and equipment such as:

- Our equipment is robust and reliable

- Our equipment is easy to operate

- Our equipment is easy to maintain

- Spare parts support has been helpful and effective

- You find FAS a professional and pleasant company with which to do business

- You have found our sales and technical staff to be knowledgeable and helpful

More importantly, you also pointed out some areas where you would like to see us improve:

- Availability of technical service personnel.

- Some of you would like to see higher line speeds for certain applications.

- You have asked for internet connectivity for all FAS Peco equipment.

- In some cases, you asked for more flexibility in applying existing FAS technology (modules) to your Film Converting challenges

- Many of you would like to see more downstream automation (packaging, roll handling)

- You would like to see more news, both technical and marketing from us

We are listening!

- FAS is in the process of recruiting additional technical service resources both in Europe and North America.

- Our engineering department is looking at ways to increase line speeds on existing equipment.

- All new equipment shipped from FAS is internet connectable. We are investigating the possibility of retrofitting this capability into existing equipment in the field.

- We are working with consultants to develop downstream automation solutions for our equipment.

- We are looking for ways to introduce new innovative solutions that will improve the performance of our existing portfolio. Visit our booth at K19 to learn more.

- We will expand our communication to you; to include the introduction of technical bulletins to relevant staff in your plants, and a more modern and user friendly webpage.

Follow us on social media, and in our newsletter “FAS News”. Reach out to your sales representative and to our Service team, they are there for you! Schedule a visit to our Innovation Center with your raw materials and test out our equipment.

Finally,

FAS is committed to an increasing role as a positive contributor to the reduction of the negative impact that plastic waste has on our environment when not managed in a correct way.

We will continue to work with and support our customers and suppliers to reduce the environmental impact of products made on FAS Peco equipment. Read upcoming issues of FAS News for more on this topic.

Feel free to contact me directly at Stefan.berg@fasconverting.com with your comments and suggestions.

I look forward to hearing from you and meeting you personally in the future.

/Stefan Berg, CEO of FAS Peco

Do you have any questions about our newsletter, please feel free to please contact Joakim Sjödin, Sales Manager, by phone on +46 72 090 89 30 or email here.

Make your travel plans now!

FAS Peco will be exhibiting at the world’s largest plastics fair, the K2019 October 16-23 in Düsseldorf Germany.

We will be located in Hall 3, Booth 3D20

Be sure to plan to stop by and say hello. Take advantage of the opportunity to meet the FAS Peco sales and management teams, as well bringing your technical questions for our service engineers. We will be demonstrating some of our state of the art Film Converting technology there. Details of the demonstration will be revealed in a later edition of FAS NEWS.

Make your way to the K.

See you there!

For more information on our live demonstration at the K2019 fair you can email Peter Håkansson here.

FAS Converting is pleased to announce our new Global Service Manager.

Lars joins us with 30+ years of experience managing service organizations around the world for Tetra Pak.

In his new role Lars will be leading the service teams based in Sweden and the United States supporting new installations and existing customers everywhere FAS and Peco do business.This appointment illustrates and reinforces our commitment to technical service support to you our customers. We are here for you and want to help you optimize the function and ultimately the profitability of your FAS Peco equipment.

You can reach Lars here with your service questions. Welcome aboard Lars!

Global Service Manager Lars Olofsson and N American Sales Manager Tom Helming visiting key customer sites in Texas.

Our market expansion continues

FAS Converting and Peco have been working to expand into new markets, bringing our technology to new generations of film extruders and converters.

We recently participated in a very successful Interplastica exhibition in Moscow. Many interesting discussions about projects were held with new prospective customers. We see potential for FAS Converting in this market Additionally, we have become very busy supplying equipment to customers new and old in eastern Europe (Rumania, Bulgaria, Hungary, etc. etc.) We have not forgotten about our legacy customers in the UK, France, Netherlands, Scandinavia, Italy Greece (etc.) where we have been busy installing equipment lately.

Meanwhile FAS Converting and Peco have been exploring Latin America and have many interesting and challenging projects quoted there in Brasil, Colombia, Ecuador, Dominican Republic, Panama, Mexico and beyond. We are very proud to announce our first ever machine placement in Cuba, this year. If you are not in these market why might this be of interest to you?

The reason is that as we enter new markets we see and learn about new applications, raw materials, methods and market demands. These challenges strengthen us as a supplier, and all of our customers benefit. When you talk with our sales team or our technical team at a show or in your plant, ask them about some of these applications. You might learn something helpful for your own organization.

To learn more about our successes contact sales manager Joakim Sjödin here.